机械制图基本视图包括(机械制图组合体的视图与形体构思)

今天我们学习《机械制图》——组合体的视图与形体构思第一部分的内容。今天的主要内容是三视图的形成和投影关系和画组合体的视图。Today we are studying Mechanical Drawing - Projection of three dimensions part 4. Today's main topic is the intersection of two revolving body surfaces.

1.主视图——自前向后投射,在正立投影面上所得的视图

俯视图——自上向下投射,在水平投影面上所得的视图

左视图——自左向右投射,在侧立投影面上所得的视图

2.三视图之间的投影关系可概括为:

主,俯视图长对正;

主,左视图高平齐;

俯,左视图宽相等,前后对应。

1.Main view - the view projected from front to back in the orthographic plane

Top view - the view projected from top to bottom on the horizontal projection plane

Left view - projected from left to right, in the side projection

2.The projection relationship between the three views can be summarized as follows

main, top view long to square.

main, left view flush in height.

Top, left view is equal in width and corresponds to the front and back.

No.1 三视图的形成

3.组合体按期形成方式,通常分为叠加型,切割型和综合型。

4.画组合体视图的方法与步骤

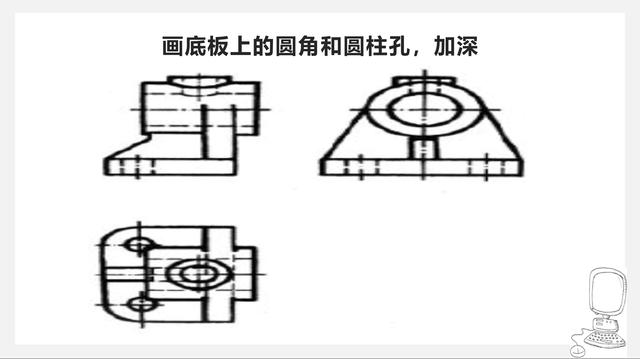

画组合体视图的基本方法是形体分析法。形体分析法是假想将一个复杂的组合体分解为若干基本体,并对它们的形状和相对位置进行分析的一种思考方法。

(1)运用形体分析,逐个画出各基本体。同一基本体的三视图应按投影关系同时画出,而不是先画完组合体的一个完整的视图后,再画另一个视图。这样既能保证各基本体之间的相对位置和投影关系,又能提高绘图速度。

(2)画每一个基本体时,应先画反映该部分形状特征的视图。例如圆筒和支承板再主视图上反映其形状特征,宜先画主视图,再画俯,左视图。

(3)在逐个画各个基本体的三视图时,还应同时思考和检查基本体表面连接处的投影是否正确,若发现错误应立即修改。例如支承板两侧面与圆筒表面相切,支承板的侧面轮廓线在俯,左视图上应画到切点处;凸台与圆筒相交,在左视图上要画出内,外相贯线;肋板与圆筒相交,在左视图上要正确画出肋板侧面与圆柱面的交线。

3. Combined body by the period of formation, usually divided into superposition type, cutting type and integrated type.

4. Methods and steps of drawing the view of the combination

The basic method of drawing the view of the combination is the form analysis method. Form analysis method is a hypothetical decomposition of a complex combination into a number of basic bodies, and their shape and relative position to analyze a method of thinking.

(1) Using form analysis, draw each basic body one by one. The three views of the same basic body should be drawn simultaneously according to the projection relationship, not after drawing a complete view of the combination first, then another view. This can ensure the relative position and projection between the basic bodies, but also to improve the drawing speed.

(2) When drawing each basic body, you should first draw a view that reflects the shape of the part of the characteristics. For example, if the cylinder and the support plate reflect their shape features on the main view, it is appropriate to draw the main view first, and then draw the top and left views.

(3) In drawing the three views of each basic body one by one, you should also think about and check whether the projection of the basic body surface connection is correct, if found in error should be immediately modified. For example, if both sides of the support plate are tangent to the surface of the cylinder, the side profile of the support plate should be drawn on the top and left views to the tangent point; if the tab intersects with the cylinder, the inner and outer coherence lines should be drawn on the left view; if the rib plate intersects with the cylinder, the intersection line between the side of the rib plate and the cylindrical surface should be drawn correctly on the left view.

No.2画组合体的视图

用三点法绘制两不等径圆柱相贯线的方法。

条件:

(1)两圆柱正文

(2)两圆柱直径不相等

作图:

(1)作出两圆柱体转向线上的相贯线点(三点)。

(2)连接a’,b’,作a’b’的中垂线,与小圆柱的轴线相交于o’。

(3)以o’为圆心,以o’a’半径为半径画圆弧,即得相贯线。

The method of drawing two unequal cylindrical coherent lines by the three-point method.

Conditions.

(1) two cylinders body

(2) the two cylinders are not equal in diameter

Drawing.

(1) Make two cylinders turning line of coherence points (three points).

(2) Connect a', b', make a perpendicular to a' b', and intersect the axis of the small cylinder at o'.

(3) Take o' as the center and draw an arc with the radius of o'a' as the radius to get the coherence line.

参考资料:文字:百度;图片:微博;翻译:百度翻译

本文由LearningYard新学苑原创,部分图片文字来自网络,如有侵权请联系。

,免责声明:本文仅代表文章作者的个人观点,与本站无关。其原创性、真实性以及文中陈述文字和内容未经本站证实,对本文以及其中全部或者部分内容文字的真实性、完整性和原创性本站不作任何保证或承诺,请读者仅作参考,并自行核实相关内容。文章投诉邮箱:anhduc.ph@yahoo.com